JXC Technology

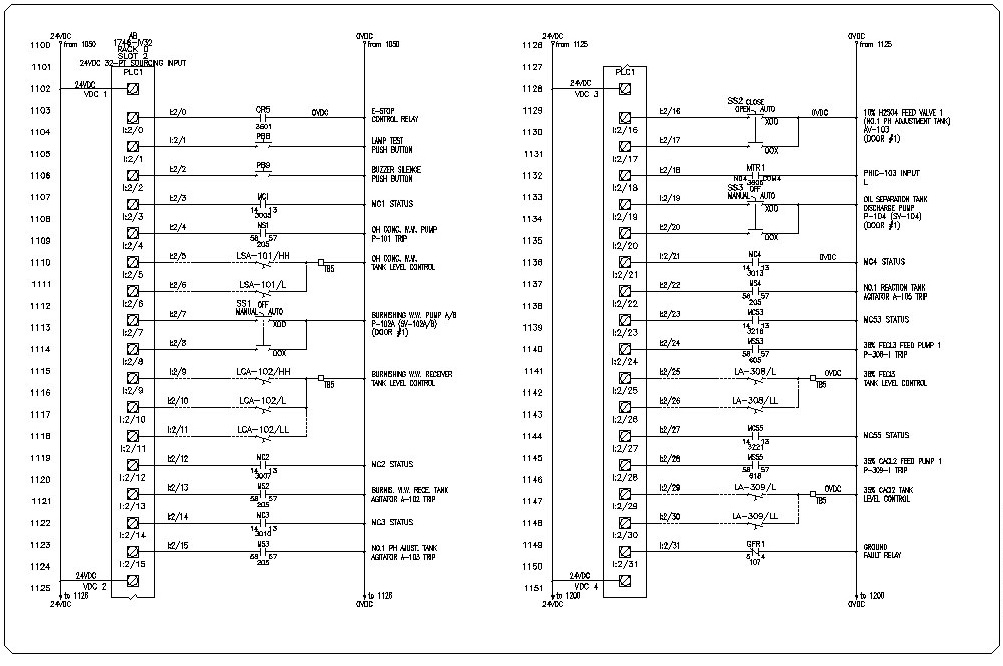

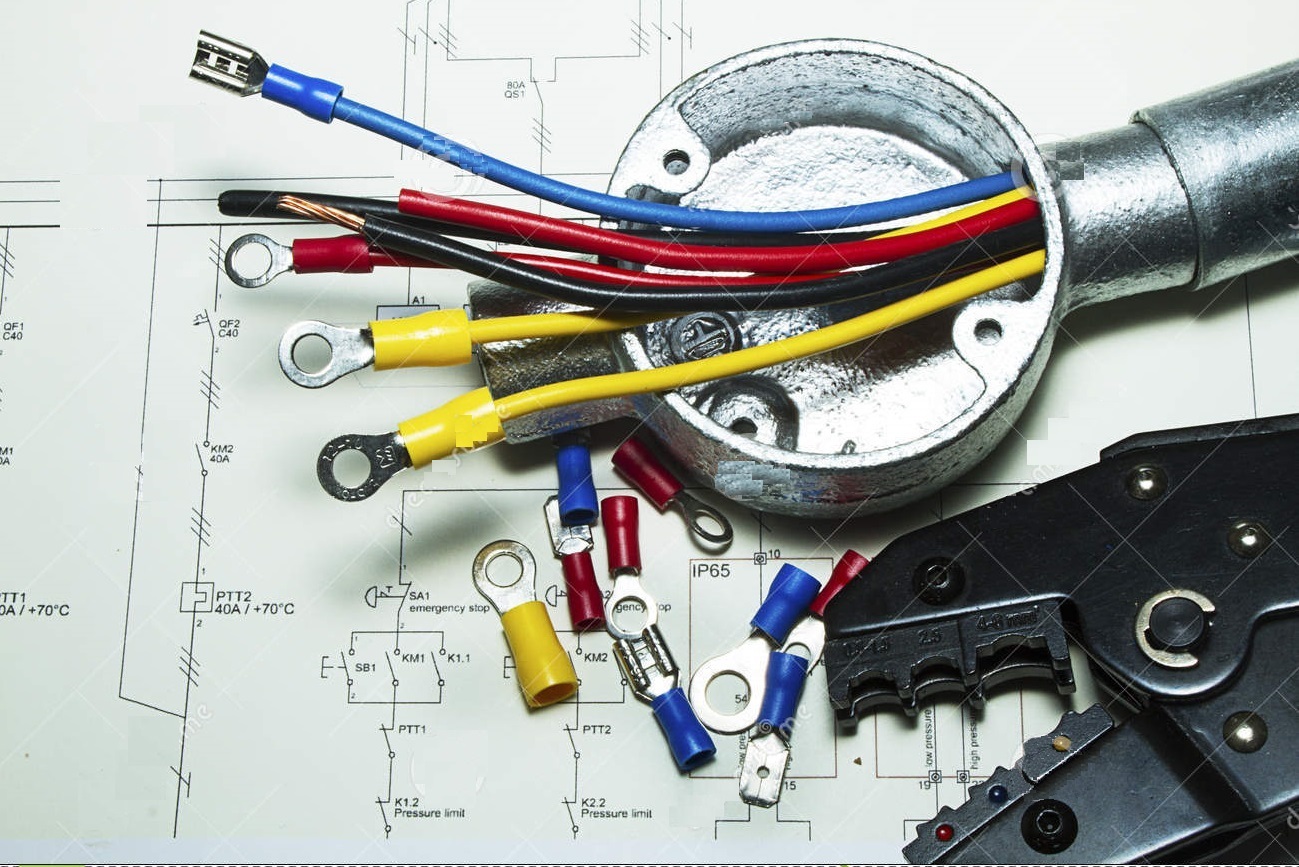

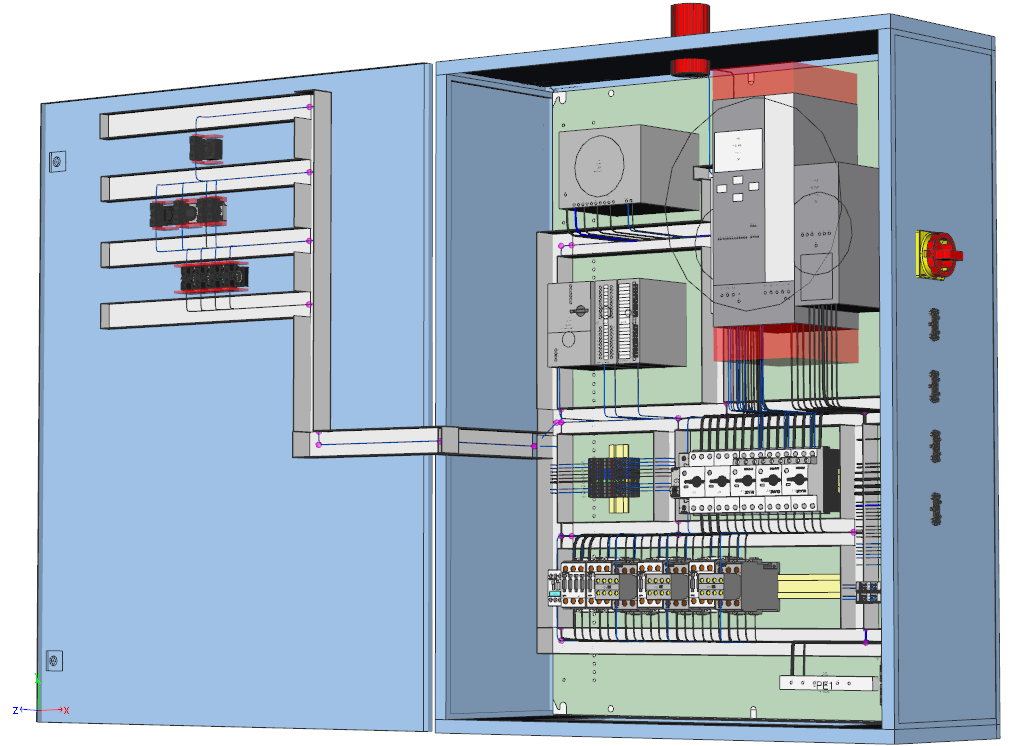

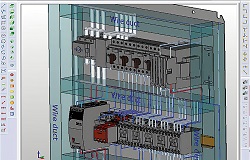

控制系统组装及布线是一个人力密集型工作,很难通过自动化设备实现,也正是因为如此,会有成千上万的错误机会出现。很多操作需要手工进行,譬如器件布局、打孔、标识、剥线、压接及布线等等。

所以经验、技术工人、科学管理系统缺一不可。

Control panel manufacturing is traditionally a labor-intensive process with few options for automation,presents thousands of opportunities for error.Most operations are done manually, including engineering and lay out; punching and drilling the back panels and enclosures; cutting, stripping, crimping and labeling the wires; installing the components; and wiring the panels.

Experience、Skilled worker、Good system can not be reduced.

轨道交通苛刻的运行环境要求更高的产品质量水平,任何细小差错都会酿成重大交通事故。

在器件选用及加工工艺等各个环节要有很高的科技水平和技术沉淀,同时更需要注重科学化的生产管理,只有这样才能造就高质量的产品。

我们为客人加工的产品及装配的系统被广泛使用在列车空调、列车牵引系统、城市轨道交通信号系统、列车网络控制系统及车载控制单元,见证了中国高铁飞速发展的光辉历程。

The harsh

operation environment of rail transit requires higher product quality level, any

minor mistake will lead to a heavy traffic accident.

High

level of technology is required in material selection and processing

technology, only

in this way can high quality products be created. Our products are widely used in train air

conditioning, train traction system, urban rail transit signal system, ground network

and on-board control unit,

把守高端制造,走在科技前沿,京昕在半导体设备制造领域有非常深厚的技术积累。

我们多年来一直专注于半导体刻蚀设备及氧化扩散设备的电气加工及配套,也非常高兴及感谢能够有机会和中国顶尖半导体设备制造商合作并分享他们每一次飞跃带来的技术提高。

For many years, we have been focusing on the electrical processing and matching of semiconductor etching equipment and oxidation diffusion equipment in China,

also we are so happy to have the opportunity to assist china leading semiconductor manufacturers in achieving their innovation, production and profit goals with advanced technologies.

定制化产品/CUSTOMIZED PRODUCTS

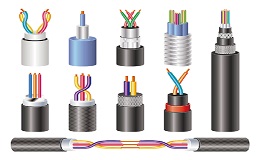

从连接器、线缆到各种电气控制单元每个方面,用我们的专长来满足客户定制化和差异化的需求。

With our professional expertise, we can meet various customized and differentiated needs of customers in connectors, cables and electronic control units.

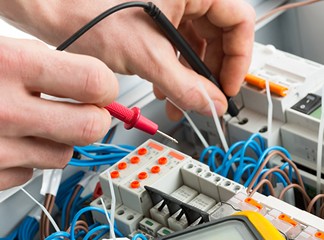

提供设备上电测试,内容包括耐压、绝缘电阻、电气功能联调等等;以便简化客户验收流程且提高产品合格率;

提供连接器及电缆产品选型服务,以确保它们的二次加工及应用场景正确无误;

提供依据国内或国际行业标准对客户线束图纸及电气接线图的审核的服务,以确保产品设计阶段没有任何差错;

提供客户声明产品的质量追溯服务;我们的质量系统可以追溯到具体生产时间、工序、操作人、来料批次等等;

Provide equipment power on test, including withstand voltage, insulation resistance, electrical function debugging, etc; in order to simplify the customer acceptance process and improve the product qualification rate.

As we know the technical specifications of connectors and cables very well, we are able to provide customers with product selection services.

And according to the industry standards to check the customer drawings, to ensure that the client's product is free of any design defects.

In addition, our product tracking service can track production time, operators, processes and material batches.